ALQUER BCRSS-3D™ is the most advanced Simulation modeling for the Operation of a 4th Gen Semi-submersible MODU Platform in any emergency | responsive scenario recognized by the international renowned expert in this area, from UK.

— A very fine use of modern technology to enhance operators' skills —

Michael Hancox, Author of the Stability and Ballast Control Compendium Book CLARKSONS OFFSHORE BROKING, London - Aberdeen - Houston - Singapore

ALQUER BCRSS-3D™ SYSTEM SUMMARY

ALQUER BCRSS-3D™ – Ballast Control and Rig Stability Simulator-3D, is a full computer based system that will provide Student practical “hands on” training for the measurable results within the shortest time period, also considering mobility.

The simulation scenarios will faithfully reproduce the appearance, functions; on a PC screen, the control panels of a semi-submersible rig. A digital mooring control panel on will allow student operation of the anchor winch motors. Dynamic, real-time coordination of all internal and external forces effecting the rig, will give the correct responses in all directions – heel, trim, roll, pitch, heave, surge, sway, yaw, rotation – along with a constant update of the rig stability data analysis screen, as draft, displacement, KM, GM, GZ, BM, FS, Center of Gravity, and Center of Buoyancy. Internal forces considered include not only the ballast and consumable systems, but also the deck load and the mooring systems and changes in these systems that are both immediate, i.e., in real-time and occur every one second. This includes movements of the rig of location due to changing anchor tensions that result from operation of the winches or environment forces. Damage effects due to added weight or lost buoyancy can be observed.

In addition to internal factors, wind and wave, current forces act upon the rig simultaneously giving real-time responses. The Instructor to simulate fresh water, salt water can initialize seawater density, or even an aerated water effect, caused by a subsea blow-out.

Concurrent with any stability problems created by the factors mentioned above, the instructor has control over the mechanical integrity of the system itself. Failures at any point, single or multiple, immediate or sequential, will be realistic and demand the same process of detection and correction required for the on-board personnel.

The objective of providing practical realistic training will be met. New personnel orientation, illustration of stability principles, rehearsal of normal, abnormal and critical operations and emergency preparedness will be greatly enhanced.

Through Instructors’ Workstation, there is access to the entire system at all times and status can be reviewed or set-up activities as desired. Using 80 plus color graphics digital screens, Instructors and Students will have field for observation of current system operating status. Instructors can save and replay exercise parameters if desired with the features of saving and restoring exercise parameters on the computer hard drives. This saves the Instructor the time of reintroducing his training exercise data with each new student group. Any saved exercise can be interrupted at any time to introduce different faults or failures.

Training Instructors will develop specific exercises that can be saved and keep its restore functions. This will be able students analyze and review main problem specifics and evaluate that most clearly teach of the stability principles, as well as emergency procedures chosen as the major objective of the training classes.

By concentrating on the key areas of realism, the students training effectiveness, Instructor flexibility, based on a digital platform, the design for the Alquer Ballast Control & Rig Stability Simulation with the 3D™ Computer Graphic Screen allows practical, economical and productive training results, even aboard MODU Semis.

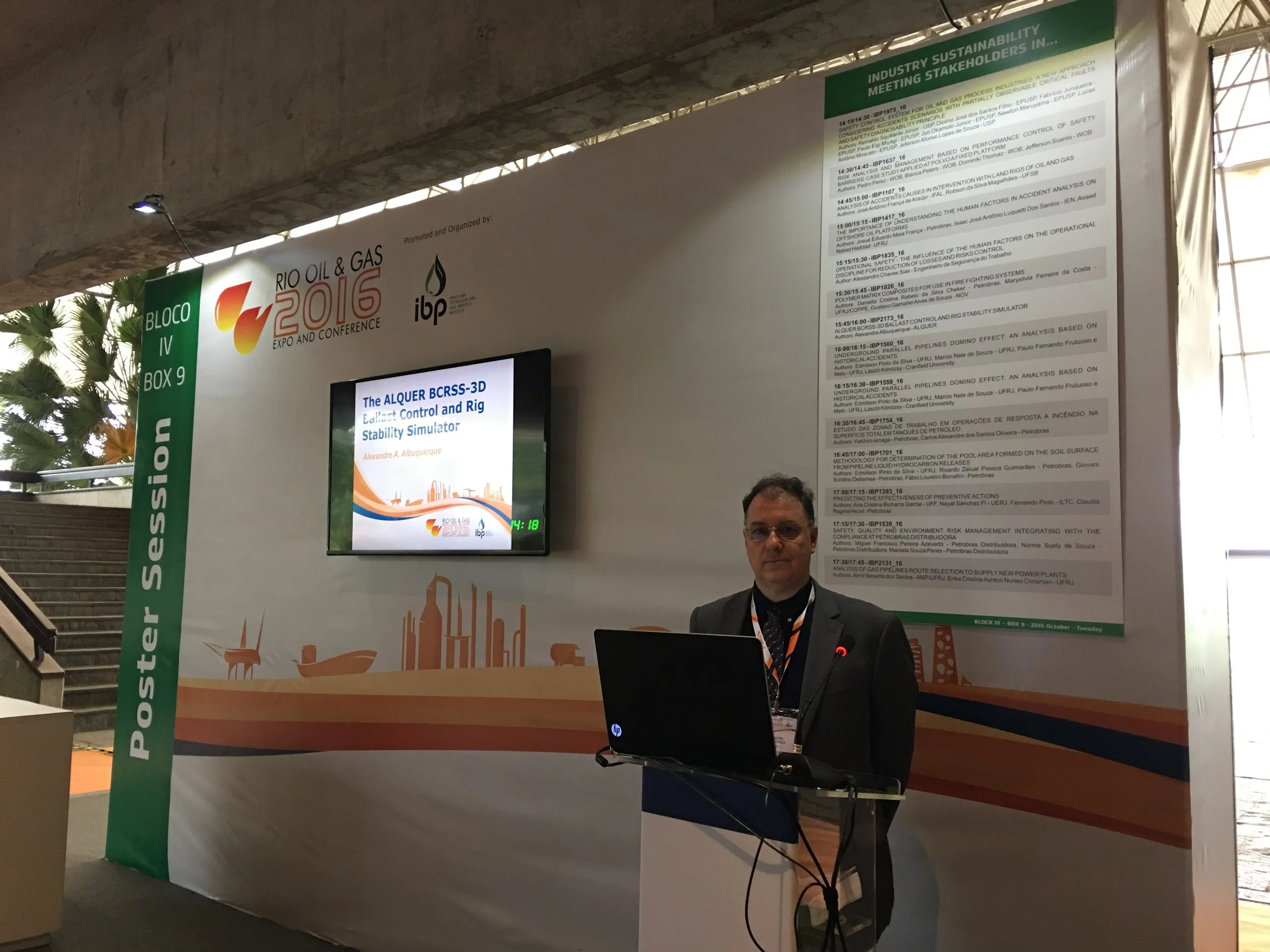

Alexandre A. Albuquerque is a Senior Engineer with extensive experience in the Oil&Gas areas, being the mentor for the first Drilling Simulator for PETROBRAS. Project Manager, Product Developer & Sole Proprietor of the ALQUER BCRSS-3D™.

More information at www.alquer.com & e-mail: alexalbuquerque@alquer.com